The timely realisation of offshore wind farms that are currently in the pipeline is in jeopardy after 2025, as multiple market analysts project a shortage of specialised heavy-lift vessels needed to install the increasing number of larger, next-generation wind turbines. Ulstein Design & Solutions B.V. is a market leader in heavy-lift design. The company offers developers, operators and contractors a fully developed and proven solution.

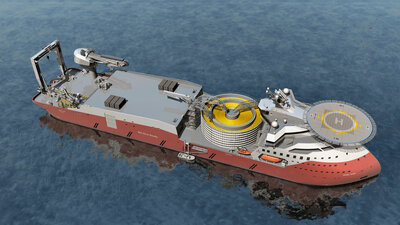

HX118 heavy lift vessel design for offshore wind foundation installation

The ULSTEIN HX118 design is the third evolution of the successful and iconic ULSTEIN SOC 5000 design, of which several vessels are currently in operation or under construction, including Heerema's 'Aegir' and Subsea 7's 'Seven Borealis'.

"We worked 4 years on the development of this design, using our unique 'ULSTEIN Blended DesignTM' methodology, CFD simulations, and knowledge gained from the ALFA LIFT design and Aegir conversion", says Ko Stroo, lead naval architect/product manager in Ulstein Design & Solutions B.V. "Combining our vast track record in heavy lift vessels with business case analysis and latest installation technologies resulted in what basically is the Mk3 version of our SOC 5000 design."

"Get delivery in 2025"

"Moreover, we have already received favourable pricings on this HLV design from multiple yards worldwide", adds managing director Edwin van Leeuwen. "So, all ingredients are available to the industry to push the button, get into a yard contract and get delivery in 2025."

Three-in-one: High lifting capacity, large deck and green power solutions

Developed to efficiently handle the next generation foundations, monopiles as well as jackets, the design features a 5,000mt main crane with large lifting heights and a large, strong open deck. Methanol powered generators, an optimised hull design and smart integration of battery systems ensure low emissions during operations and when in port.