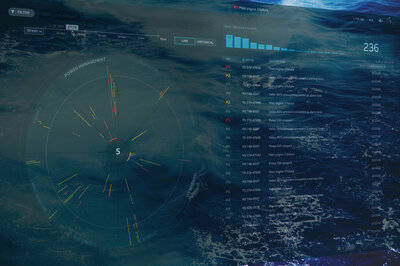

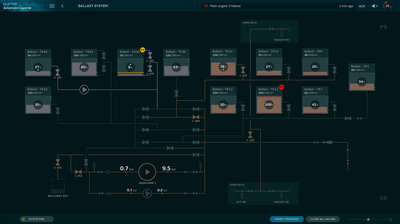

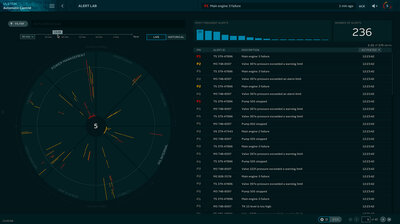

ULSTEIN IAS is a scalable and flexible automation system. The graphics are developed with the attention to provide a user interface that lets the ship operator respond with higher efficiency.

As the amount of sensors, actuators and information available on the vessel increases rapidly, the control systems have to take account for this and efficiently provide the information to the end users.

Scalable and prepared for the future automation system based on the ULSTEIN X-CONNECT flexibility

The new ULSTEIN IAS control system provides a seamless integration between control systems, power management systems and energy management systems. This will enable future functionality, as our platform expands.

Information in one place

"We believe that the first step in making a good system that supports the operator, is to present information in a clear and precise manner in one place. This will help the operator to safely survey the ship's distributed systems. This is one of the fundamental ideas behind the ULSTEIN BRIDGE VISION, a vision of the future ship bridge," says managing director Gunnar H. Hide at Ulstein Power & Control AS.

Approved without remarks

Two subsea rock installation for Jan De Nul Group at AVIC Weihai Shipyard Co Ltd in China, will be duly prepared for the new reality, and the ships will be the first with the new ULSTEIN IAS automation system. The system was approved without remarks by Bureau Veritas. The automation delivery has also been presented to the customer at a Factory Acceptance Test (FAT).

Radical change

"New technologies can radically improve the efficiency of how a ship is operated. The future is about embracing these possibilities, developing interfaces for safer and more efficient operations," says Hide.

ULSTEIN X-CONNECT® is the back-bone of our

new wave breaking automation system. All solutions coming from ULSTEIN will be

built on the same architecture in the future, and with this as building blocks

? more autonomous systems will be the outcome.