Hybrid Power

Powering sustainable operations with emission-free capability

Our hybrid system enables fully emission-free periods, helping you run cleaner marine operations while significantly reducing fuel use and operational costs.

What is battery powered hybrid solutions

The Ulstein Hybrid Power Solution introduces a new element integrated into a ship's central power system, where the added 'grid support functions' give new opportunities for flexible vessel operation. The system solution comprises battery energy storage, power conversion, and energy management as its main elements.

The holistic approach to vessel integration ensures the system works seamlessly with the ship's existing power systems.

Reduced emissions and engine load

Flexible power generation

Operating within the sweet spot of energy efficiency! With a VSG (variable-speed generator), the combustion engine speed can be regulated to match the vessel's load demand, increasing the overall efficiency of the power system.

Reduced emissions and engine load

Zero-emission mode

In zero-emission mode, the vessel is powered exclusively by the energy storage system. One significant benefit is a cut in local emissions. The zero-emission mode functionality can be scaled from minutes of operation in a harbour, to operations of vessels with predictable schedules in terms of activity and energy

Smart DP operations

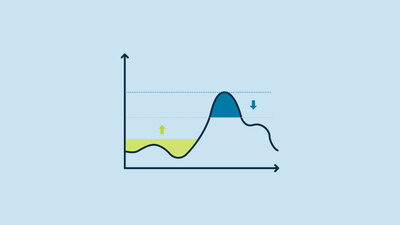

Peak shaving

When power demand fluctuates, combustion engines may not be operating efficiently. With hybrid solutions, this is a problem that is easily avoidable. The hybrid power system increases efficiency, handling the peak loads by smoothing the load of the engines. This process prevents unnecessary start-up of standby engines, improving overall vessel efficiency.

Smart DP operations

Spinning reserve

For operations requiring power supply redundancy, such as DP operations, more combustion engines need to be running than strictly necessary to support power demand. In these cases, the hybrid power system can act as a source of spinning reserve energy, enabling the vessel to operate safely with fewer engines running.

Curious about how we can assist you?

We deliver complete power and automation solutions for efficient, future-ready marine operations. From hybrid propulsion to smart control systems, we help you stay compliant, connected, and competitive—worldwide.

Benefits with hybrid power

- Improved energy efficiency

- Reduced fuel consumption

- Reduced emissions, also emission-free in some operations

- Less wear and tear

- Peak shaving for best operational results

- Reduced operational expenditure

Hybrid Power brochure

Dive into the details about:

- The benefits of hybrid power

- Project execution

- A holistic approach to customer needs

Let’s talk. We’re here to help.

Have a question or an idea to share? Send us an email, give us a call, or fill out the form. We’ll get back to you as soon as possible.

Rolf Ottar Rovde

- Description

- Sales Manager

- Affiliation

- Ulstein Power & Control AS

Peter Pilskog

- Description

- Managing Director

- Affiliation

- Ulstein Power & Control AS

Per Einar Moldskred

- Description

- Service Manager

- Affiliation

- Ulstein Power & Control AS