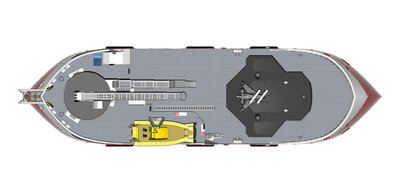

SX250

The ULSTEIN SX250 is based on the proven TWIN X-STERN solution, which ensures high operability and excellent seakeeping capabilities. It measures 47 metres in length and 12.5 metres in width, accommodating 32 to 40 people on board (POB). The vessel has a maximum speed of 10 knots and can operate in conditions of up to 2 metres significant wave height (Hs). Safety is a major focus, with people and goods transferred via a basket in an Offshore Passenger Transfer System (OPTS), Bring-to-Work System, or conventional gangway.

Primary specifications as built

Turning visions into reality

The SX250 is a versatile and innovative vessel designed for efficient offshore wind farm maintenance. Thanks to its flexible design, we can customise it to meet your specific operational needs, ensuring maximum efficiency and cost-effectiveness.

SX250 – Walk-to-work vessel

The ULSTEIN SX250 transforms offshore wind farm servicing by bridging the gap between Crew Transfer Vessels (CTVs) and Service Operation Vessels (SOVs), introducing new service logistics saving CAPEX and OPEX.

- Cost efficiency:

- The SX250's ability to reduce CAPEX by at least 50% compared to an SOV and OPEX accordingly makes it an affordable alternative for operators looking to manage their budgets effectively.

- Operational versatility:

- The ULSTEIN SX250 is built on a flexible platform and can handle many of the same tasks as conventional SOVs. The vessel can be customised with different arrangements and topside equipment, allowing it to adapt to various operational needs and making it easy to repurpose for new tasks.

- Enhanced safety and comfort:

- Equipped with gangways and baskets for personnel transfers, the ULSTEIN SX250 reduces the risks of climbing a ladder when entering the turbine, enhancing overall safety. The crew is also less exposed to wear and tear due to the lower transit speed and higher comfort compared to smaller crafts.

- Efficiency in operations:

- With accommodation for 32-40 people, the ULSTEIN SX250 can stay longer in the field. Time saved on commuting can be spent on actual work. The agility makes it particularly suitable for scheduled maintenance during the summer, ensuring timely and effective service.

- Environmental benefits:

- The vessel consumes less fuel than larger SOVs and, without the need for daily commutes, saves fuel compared to CTVs. This results in lower operational costs and reduced emissions. Further, its reduced energy consumption facilitates the transition to zero-emission operations by enabling the integration of alternative fuels. By minimising its environmental footprint, the ULSTEIN SX250 aligns with the industry's push towards more sustainable operations.

Alternative topside configurations on the ULSTEIN SX250

The vessel can be customised with different arrangements and topside equipment, allowing it to adapt to various operational needs and making it easy to repurpose for new tasks.

Cutting costs in W2W operations

Offshore wind farms are currently serviced using Crew Transfer Vessels (CTVs) or helicopters for day operations, and Service Operation Vessels (SOVs) for extended periods. What if there were a CAPEX-smart design that reduces building costs by over 50% compared to an SOV and supplement the SOVs on most tasks?

Get in touch

Geir Heltne

- Description

- Sales Manager

- Affiliation

- Ulstein Design & Solutions AS