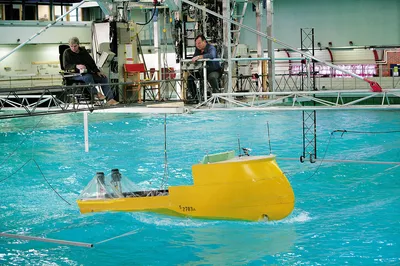

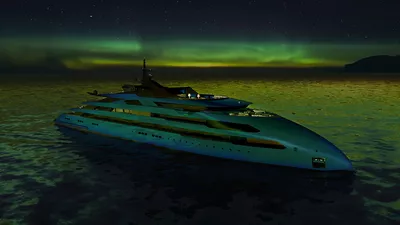

“The new ULSTEIN AX104 with its ULSTEIN X-BOW™ from Ulstein Design AS has no bulb, and has a slender, characteristic bow design with an inverted flare; in other words, the bow slopes backwards instead of forwards. The intention is that this should result in less loss of speed when it is moving in seas. It is an interesting idea, and we have followed the model closely through still water tests and tests with various wave heights and speeds,” says the project manager at Marintek, Magnus Tvete.

The vessel will also be one of the first anchor-handling vessels in the world with diesel-electric propulsion. Tvete was positively surprised by the tests with the model:

“I thought the hull design would result in some spray, but in fact the shape resulted in very good carrying. The resistance level was relatively low compared with conventional designs at the gauges that were tested. This is probably due to the gentle entry angles into the waterline,” he says.

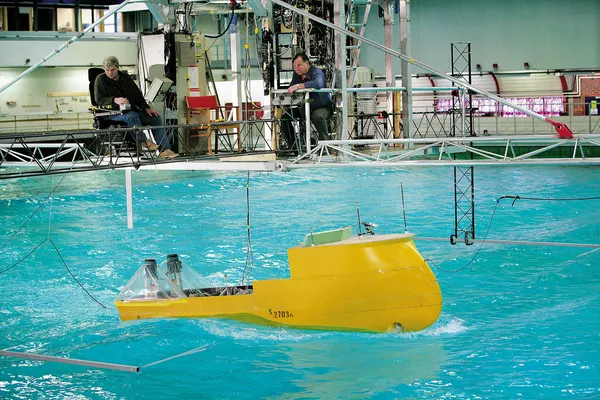

Researchers Magnus Tvete and Rolf Riksheim at Marintek looked forward to study the model tests of the ULSTEIN AX104.

I thought the hull design would result in some spray, but in fact the shape resulted in very good carrying. The resistance level was relatively low compared with conventional designs at the gauges that were tested. This is probably due to the gentle entry angles into the waterline.

No slamming

“Some of the most common accidents that occur on offshore vessels involve the sea breaking the wheelhouse’s windows. This happens because ordinary, traditional hull shapes throw the sea forwards and upwards and the hull dives deeper, says Tvete.

“Prior to the tests on the ULSTEIN AX104 model, we thought that the wheelhouse windows could also be smashed with this vessel, due to the fact that shape of the bow of the ULSTEIN X-BOW™ means that no slamming occurs. Without the warning slamming gives, I thought a captain could easily run too fast, and the sea would therefore be able to creep up the side of the vessel and smash in the wheelhouse windows. The tests on the model, however, showed that almost no sea came up onto the bridge deck at all, even in extreme weather conditions with six metres significant wave height and a wave period of nine seconds. Under these conditions, the model maintained a good service speed.

No extreme weather damage

The senior hydrodynamics designer at Ulstein Design, Øyvind Gjerde Kamsvåg, explains the principles behind the new forepart design: “A different volume distribution than usual was introduced. A much larger, much more slender, facing volume was introduced. The large volume in the bow means that the forebody floats better and dives less when it meets waves. This means that no slamming occurs and that the hull moves through the sea very gently,” he says.

Senior hydrodynamics designer at Ulstein Design, Øyvind Gjerde Kamsvåg, designed the hull, and followed closely the model tests of ULSTEIN AX104.

The large volume in the bow means that the forebody floats better and dives less when it meets waves. This means that no slamming occurs and that the hull moves through the sea very gently,”

"Never seen anything like it"

Kamsvåg designed the hull and is happy to see that the results live up to expectations.

“The model tests showed that the ULSTEIN X-BOW™ functions completely as intended and I am really pleased. Even high and choppy waves did not result in sea spray on the bridge deck.

"I’ve never seen anything like it. The likelihood of extreme weather damage to the forebody will be reduced. Besides this, the smooth forepart goes all the way up to the bridge deck and this means that all the deck equipment that is normally exposed to the wind, weather, and icing is protected. Little spray will anyway mean that there will be no problems with icing,” he says.

Increased comfort

Reduced accelerations and retardations means higher average speeds in seas, which reduces the need for power and fuel consumption. This also results in a significantly improved working environment onboard.

“Safety during navigation will be better, and you will end up with higher operability. Noise and vibrations will be strongly reduced, and thus comfort will increase,” claims Kamsvåg.

The model tests also revealed potential for improvement.

“We saw that a wave built up in front of the bow, we have therefore fine-tuned the bow’s entry so that it moves less water. The vessel has therefore become even more efficient,” he explains.

Exciting

A group leader at Marintek for many years, Rolf Riksheim, likes innovative designs: “It is interesting and also quite nice that people are thinking new when it comes to hull design. Little work has been done on developing new hull designs for supply vessels, and there has been no focus on speed and fuel consumption. Supply vessels have remained almost unchanged for 20 years,” he says.

Marintek has tested vessel models for 65 years

The 260 metre long ship model basin at Marintek in Trondheim is the only one of its kind in Norway, and is the largest in the Nordic countries. In addition to this, the research institute has a 50 by 80 metre sea basin. With the help of the basins, one can simulate wind, waves and currents, and one can test models of new vessel types before actually commencing construction of the vessels. The living research environment at Marintek helps to develop and improve vessel types for all the world’s oceans.

“We test new vessel models every week. The vessels are subject to different requirements such as they should have good sea keeping qualities, not produce much noise, and so on. Our model tests allow us to check that the requirements set out between the shipping companies and shipyards are met. We test all types of vessels and have solid experience. We often discover things that can be improved, and we then suggest improvements to the hull and propellers that can result in greater speed, lower consumption or gentler movements,” explains Riksheim.

The ship model basin at Marintek was opened in 1939 and was originally 170 metres long. The facility was intended to serve the shipping industry and the growing shipyard industry in Norway. It has also always been used by the Norwegian University of Science and Technology (NTNU) in its teaching of shipping students. The basin was extended to its current length in 1981 and the sea basin was built at the same time.

GLOSSARY:

ULSTEIN AX104:

A vessel in Ulstein Design’s A series, where the A stands for anchor handling. The X stands for the bow design of the ULSTEIN X-BOW™. 104 is a serial number.

ULSTEIN X-BOW™:

A new bow concept from Ulstein Design AS. The bow slopes backwards rather than forwards and there is no bulb. This results in little or no spray on deck, and no slamming.

Bulb:

A protrusion from the hull, primarily below the waterline that improves the wave system and resistance.

Slamming:

The impact of waves against the hull.

Spray:

Sea spray.