Designed for the lowest possible emissions

The fishing company Bluewild will replace the trawler 'Langenes' from 1986 with a new building to fish its cod, pollock, and haddock quotas. In addition, Bluewild has a license to fish shrimp to achieve high vessel utilisation all year round. These fisheries require different levels of towing power.

The new trawler will have an efficient hybrid system with two propellers that combine battery power with diesel-electric and diesel-mechanical propulsion. This will make the fishing vessel more fuel-efficient than a trawler with traditional propulsion.

"Through analyses and tank tests, we estimate that this hybrid system, together with other energy-saving measures on board, will give at least a 25 per cent reduction in fuel consumption and emissions compared to a similar modern trawler performing this type of combination fishing and the savings can in some operations exceed 40 per cent," says Frode Sollid, system architect in Ulstein Design & Solutions AS.

Sustainable fisheries that challenge conventional solutions

"We have teamed up with the fishing company Bluewild over a longer period to challenge the conventional solutions within the trawler industry", Sollid continues.

"Shrimp fishing requires a large towing force, while the power demand is not as great for whitefish trawling and when transiting to and from the fishing grounds, the power requirement is even lower. The hybrid propulsion system is adapted to both fisheries. If designing and planning only for maximum engine power to ensure that the vessel can perform all the assignments in the operation profile, the vessel will be expensive to operate and lead to unnecessary emissions during the less energy-intensive operations. In such development work, it is important to ask, "Can this be done in another way?"

The first step towards lower energy consumption

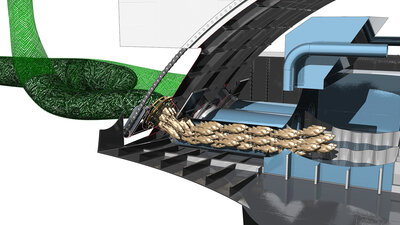

The first step in the process towards lower energy consumption was to map how the vessels use their power system and look at the essential properties of the system. For a freezer trawler, the dominant mode of operation is trawling, while the vessel rarely transits at high speeds. Together with the shipowner, the choice was made to focus on increasing the efficiency during trawling. It was, therefore, chosen to install two propellers instead of the traditional solution with one propeller because the increased propeller area increases the vessel's towing efficiency. The propellers are placed in separate skegs in a twin-skeg hull, which provides significant advantages in terms of placement of the propulsion equipment and increases the propeller efficiency.

More possibilities for energy saving with double propeller

Once you go for two propellers, you get new opportunities to operate the vessel in ways you do not have on ships with only one. By calculation, two propellers use less energy together than one propeller to achieve the same towing power. Also, one of the propellers can be loaded more than the other to steer the vessel. Generally, fishing vessels get a significant added resistance when compensating for wind, waves and currents with large rudder angles. The power requirement will be further reduced by delivering part of the steering power with the propellers.

Additionally, the ship is equipped with rudder nozzles instead of the usual rudder behind the propeller. During the model test at Sintef in Trondheim, it was demonstrated that the rudder nozzles were significantly more efficient than ordinary rudders. With this solution, the trawler will be very efficient when trawling in challenging weather and during manoeuvring.

A solution that can reduce emissions in the fishing fleet

Ulstein's team has taken into use their experience from developing the propulsion systems on the anchor handling vessels Olympic Hera and Olympic Zeus, which were nominated for the Green Ship Technology Award, and linked this to the analyses of the operational requirements of the trawler.

"Both for an anchor handler and a trawler, great demands are placed on towing power. We have looked at how reference vessels in the fishing fleet are used, and most of the time, they are used for trawling, while only a relatively small part of the time is related to sailing, and then usually at a relatively low speed. In consultation with the shipowner, a conscious choice was made to prioritise the properties during trawling and optimise the hull for minimum resistance at moderate speed", says Sollid.

"Energy savings have been considered throughout the project, and these solutions combined will contribute to a significant potential for reductions in fuel consumption and emissions in the fishing fleet."

Holistic design development

Ship designer Bjørnar Hatløy, who has led the development of the ULSTEIN FX101 design, follows up:

"We have considered this holistically and have especially worked with performance, safety and functionality," he says and elaborates:

"We have looked at how the very different operations can be carried out as economically and energy-efficiently as possible. Based on this, we have designed an optimal system architecture for efficient performance at low, medium, and high power consumption. The system architecture must be able to handle the entire span of operations with low environmental emissions".

Can be trawling in diesel-electric mode

"During the most energy-intensive operations, such as shrimp fishing with quadruple trawl, both main engines will be used, mechanically connected to each propeller to be most efficient at high power. However, the vessel should also be able to operate efficiently with lighter trawling that requires less engine load, and it has been enabled to do so in diesel-electric mode with only one of the main engines in operation. Operating time between the engines will be reduced, while the operative engine will be allowed to run more optimally. The propellers can then run at a very low speed, which gives very high efficiency during trawling; the vessel will be quieter, and little power is needed to operate the ship. In this way, the advantages of diesel-mechanical and diesel-electric power systems are utilised, while many disadvantages will be avoided.

Battery as part of a hybrid package

The Battery Energy Storage System (BESS) is a central part of the hybrid power system and has the following functions:

- Engine support: The battery actively assists the main engines, especially when the trawler operates on only one diesel engine in diesel-electric mode. Substant amounts of energy are saved by letting the battery take care of the short-term increases in power demand, such as when the vessel turns during trawling.

- Response in the power system: The solution's battery system has large power reserves and quick responsiveness. With battery assistance, the diesel engine will be able to work dynamically and handle load increases more easily.

- Reliability: The battery system increases the redundancy and uptime of the power grid should a fault occur.

- Storing return power: The trawler has electric winches with power regeneration. When the trawl is slowed down, energy is released to the grid. This return power can be stored in the battery and made available later.

- Reduced emissions at quay: The battery system has a large energy capacity (approx. 1,130 kWh), which can not only support the ship in case of extra power needs but also means that the vessel can stay quayside for many hours before a diesel engine must start or shore power connected. The vessel is also equipped with a modern shore connection that can fully utilise the port facilities that are currently under development. This means that the entire trawler can be supplied from shore, and the large battery can also be charged by shore power. This will help to eliminate the need to run diesel engines during quayside.

Ship designers and integrators - not only developing a vessel but an entire system

Frode Sollid continues: "The people at Ulstein Design & Solutions are naval architects and integrators. We do not just develop a vessel but an entire system. When we design a ship, we structure our work around the knowledge of what the ship will do, the work operations, and where the ship will be operating."

"Knowing how much power is needed throughout the year to perform the various operations under different conditions, we have defined a hull adapted to the environment in which it will be used. With the good experiences of the X-BOW® in other ship types, we have developed a hull that is tailor-made for this type of ship. An X-BOW provides a volume distribution that we benefit from when arranging the foreship. With the choice to optimise the hull lines for a speed of 10-12 knots, the vessel has larger capacities than one can typically expect from a fishing vessel of this length".

Flexible and future-oriented

"The hybrid propulsion system of the Bluewild trawler is a very future-oriented solution that makes it possible to conduct different types of fishing efficiently and ensures future opportunities for new fisheries that may come. Many elements together make this trawler a masterpiece", concludes Sollid.