"Oceana Offshore decided to go for our proven PX105 design. Our contract with Oceana includes the designs and an extended main equipment package, as well as engineering and purchase support," said senior business advisor Erik Andreassen in Ulstein Design & Solutions AS when the contract had been signed. He continued:

"We are grateful for the trust placed in us and look forward to entering this project together with a new and future-oriented partner. We wish to thank the teams from both sides that have been working hard together over a long period in order to finally enter into this agreement. We believe Oceana Offshore will be satisfied with their new vessels."

"We are very pleased to have Ulstein Design & Solutions AS as the designer of the first vessels to be built in our new shipyard in Itajai. Hopefully it will be a start of a long-lasting partnership between our companies," said Oceana Estaleiro's CEO, Paul Kempers.

The vessels for Oceana are purposed for work in the Brazilian oil industry.

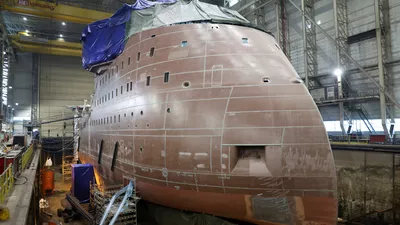

The PX105 design is a large platform supply vessel with accommodation for 23 people. The vessels will be 88.9 metre long and 19 metre wide. With a DWT of 4,700 tonnes they comply with Petrobras' PSV 4500 tender. These vessels have a high operational window and can take on complex assignments far from shore. They come with the X-BOW® hull line design feature, in which slamming and abrupt stops from waves are eliminated. The vessels are cost-effective and fuel-saving, and the crews get more efficient rest, which also increase safety.

"Oceana Offshore S.A. is funded by the solid investment and engineering partners P2 Brazil and BNDES. Their yard, Oceana Estaleiro, is currently under construction in Itajai in the region of Santa Catarina, which is a maritime cluster of yards and related businesses," commented Erik Andreassen.