Great Lakes Dredge & Dock Co. LLC (GLDD) is the U.S. leading dredging company. The first vessel will be constructed by Philly Shipyard and is expected to enter operations by Q4 2024 to serve the U.S. offshore wind market.

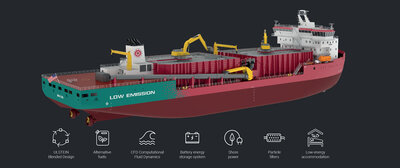

"World-renowned engineering firm Ulstein Design and Solutions B.V. was commissioned by us to design the vessel using state-of-the-art technology, equipment and automation", states Eleni Beyko, Great Lakes Dredge & Dock's Senior Vice President Offshore Wind. "The design was reviewed and approved by the American Bureau of Shipping ("ABS") and will be built with best-in-class safety and low emissions standards (LEV, Sustain2)."

To reach the low emission and sustainability goals, the vessel design includes EPA Tier 4 engines, plug-in shore power connection for loading in ports and battery packs for peak-shaving. The vessel is also able to run on biofuel to reduce its CO2 footprint and is equipped with active emission control technology to minimise NOx emissions.

In the concept phase, the Ulstein Blended Design method was used to enhance cargo efficiency, boost the GLDD business case, and reduce overall fuel consumption.

"It is a privilege to work together with the GLDD newbuilding team. Their vast experience in U.S. shipbuilding, combined with our expertise of rock installation vessel design, was essential in creating this unique vessel for U.S. offshore wind sector", says Ko Stroo, lead designer in Ulstein Design & Solutions B.V.

Main dimensions of the vessel are:

- Loa 140.5 m / 461 ft

- Lpp 134.9 m / 442 ft

- Beam (moulded) 34.1 m / 112 ft

- Depth (main deck) 10.7 m / 35 ft

- Draught (operational) 7.0 m / 23 ft

- Service speed 12 kn

- Installed power 2 x 3,150 kW - 2 x 2,250 kW

- Propulsion thrusters 2 x 2,500 kW

- Retractable thruster 2 x 1,200 kW

- Tunnel thrusters (fwd) 2 x 900 kW

- Positioning system DP 2

- Class ABS

- Rock hold capacity 20,000 t

- Complement 45 P

Ulstein Design & Solutions B.V. specializes in the design and development of game-changing ships for the offshore energy market. Sometimes brilliantly simple, sometimes necessary complex. We push for sustainable solutions. Besides newbuild designs, Ulstein Design & Solutions B.V. is actively involved in consultancy and feasibility studies for upgrading vessels.