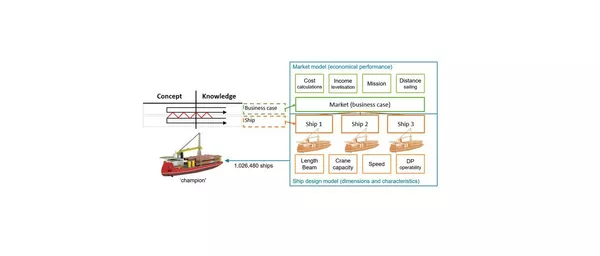

These two models are used to generate millions of 'ship design ? business case' combinations. These designs subsequently compete on their calculated economic performance and provide a clear understanding on which main vessel characteristics and dimensions are optimal for the intended business case. The results will provide a clear answer to which design will be the future 'champion'. By changing the input for the market model, the effect of different future scenarios on the design of the 'champion' can be studied.

Example: Heavy Lift Crane Vessel (HLCV) - monopile case study

The offshore wind industry is characterized by large growth in market demand, ever increasing turbine sizes and geographic expansion. Different future scenarios can have great impact on the business case, optimal vessel size and crane capacity. The Ulstein Blended Design method is specifically created to investigate these types of markets. It enables Ulstein and its clients to develop a future proof heavy lift crane vessel with the most robust business case and most economical ship design.

Typical assumptions for an HLCV Blended Design model are:

- Market model based on different monopile size forecast curves and probability densities

- Economic performance based on Return on Investment (ROI) or Cost per foundation

- Newbuilding cost based on area of construction (USA, Europe or Asia)

- Standard wages, operational cost, fuel cost and finance cost

- Variables: length, beam, depth, draught, DP operability, service speed, crane capacity

- Calculated: Cb, propulsion power, DP power, freeboard, stability, deck area, monopile cargo capacity, OPEX, CAPEX, VOYEX & economic performance

- Operability based on DP capability in selected wave climate nautical zone (DNV-RP-C205)

Results coming from the HLCV Blended Design model :

Optimization of following parametres for selected scenarios:

- Main dimensions (length, beam, depth, draught, Cb)

- Installed power (main engines and thrusters)

- Vessel speed

- Crane capacity

Effect of different input scenarios on optimal ship design:

- Future scenarios (turbine size, water depth, technology paradigm shift)

- Economic performance preference (ROI, cost price leadership, profit)