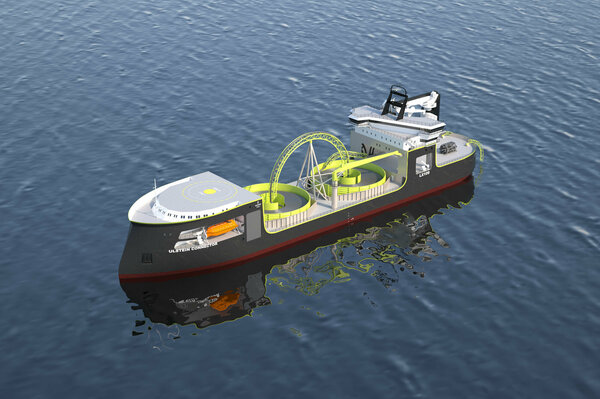

A unique feature is the ULSTEIN Cable Arch connecting the forward and aft turntables, allowing to load and lay one continuous cable of up to 12,500 tonnes. This capacity was made possible by positioning the turntables into the hull instead of their conventional location on deck, improving vessel's stability. A feature also applied by Ulstein on a rock installation vessel currently under construction. This approach resulted in a slim vessel that can transport and lay cable much more efficient than conventional vessel designs with larger beams.

Locating the a-symmetrical bridge aft, with the cable passing underneath, provides clear and unobstructed views on the cable lay work deck and cable stingers aft and the turntables forward. Furthermore the vessel features a large hangar with ROV moonpool and workboat storage. In combination with the well-known X-BOW® and X-STERN® hull features, this results in a very cost efficient, safe and comfortable platform with superior operational uptime and transit speed compared to more traditional cable lay units.

"With this design we like to bring the cable lay market to the next level," says Edwin van Leeuwen, Product Management Leader at Ulstein Design & Solutions. "Using the ship and equipment knowledge available in the Ulstein Group, resulted in a revolutionary, truly integrated design, based on existing technologies. By focusing on a dedicated vessel for cable lay projects, we have been able to dramatically improve on project economy, seakeeping behaviour and fuel economy."