Recently. Olympic announced a 5-year contract with Aker BP for the newbuild CSOV, Olympic Notos, which was delivered in November 2024. The vessel will be modified at Ulstein Verft in 2026 to meet the specifications and requirements for servicing unmanned installations on the Norwegian shelf. Ulstein awarded a contract to retrofit the CSOV vessel… | Ulstein

Walk-to-work operations are well established in the offshore wind market and oil & gas operations, and Ulstein was one of the first movers in designing such vessels, starting with the Seaway Moxie, delivered in 2014.

Several other vessel designs have been contracted in between these vessels, of which several are under construction at various yards, introducing pioneering solutions to this segment, such as hull innovations (X-BOW, X-STERN), power & control solutions (ULSTEIN POWER VSG), and propulsion breakthroughs (TWIN X-STERN).

Either in the offshore wind or the offshore O&G markets, walk-to-work operations are about efficient onboard logistics, excellent manoeuvrability, high operability, and comfort.

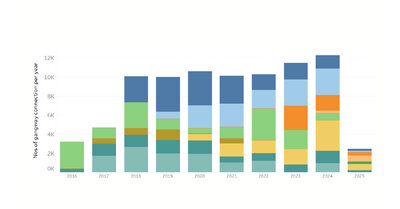

Illustration below: Number of gangway connections per year (each colour represents a different vessel)

Ulstein introduced the X-STERN following market insights showing that these vessels operate stern first in about 70 % of the time when infield. With the X-STERN, the impact and vibrations at the stern while on DP are significantly reduced, similar to the X-BOW effect in the bow. The first feedback from a DP operator stated that "With the stern towards the weather, we experience absolutely no slamming and vibrations, not even when we are in transfer, and people love it. They get complete rest in between their maintenance shifts".

The later innovation, the TWIN X-STERN, introduced main propulsors fore and aft, another improvement to seakeeping and comfort.

How walk-to-work has transformed offshore wind services

As offshore wind farms are established further from shore, overnight stays become necessary. The walk-to-work capability of modern service ships for far-from-shore offshore wind farms has transformed the daily routine of technical crews. Transfers are conducted safely and efficiently, allowing service technicians to return to their high-standard accommodation vessel at the end of each workday.

Before the introduction of active motion-compensated personnel transfer gangways, technicians were primarily transferred to turbines via small crafts, requiring them to climb ladders. These transfers are often restricted by wave conditions.

With the W2W gangways, service can now be performed in rougher seas, significantly increasing operational days by weeks, even months, each year. Crew Transfer Vessels are still widely used as an additional method, enhancing an Offshore Wind Vessel's capacity to service more turbines in a single day.

A crucial part of the job for service technicians is waiting for the delivery of spare parts. Nowadays, the vessel carries almost everything needed to maintain the wind park. Once the required spare part is identified at the turbine, the technicians call the vessel, and the part arrives within an hour. If the rare event that the spare part is not on board, the daughter craft can be dispatched to the base to retrieve it. At regular intervals, the vessel returns to the base to change the team of technicians and replenish supplies.

W2W vessels from Ulstein

The total number of walk-to-work (w2w) vessel designs and redesigns by Ulstein now counts 22, of which 16 are currently in operation.