X-BOW®

The ULSTEIN X-BOW®, the inverted bow concept, redefined marine engineering. The bow concept was launched in 2005, together with the first shipbuilding contract, and gained immediate interest from shipowners. The X-BOW hull line design has been tried in most weather conditions.

Transforming sea travels with the X-BOW

Major benefits of the inverted bow concept.

- Efficient power

- The X-BOW design enhances fuel consumption by offering improved hydrodynamics.

- Gentle wave entry

- The unique shape ensures a soft encounter with oncoming waves, reducing jolts and jerks.

- Whisper-quiet operations

- Its structure significantly minimizes noise and vibration, providing a comfortable vessel environment.

- Minimal slamming

- The sloped design reduces bow impact, ensuring smoother rides in rough seas.

- Optimised rest periods

- The reduced vessel motions enable better resting conditions for the crew.

- Smooth accelerations

- The X-BOW ensures gentler accelerations, preventing sudden jolts during speed changes.

- Steady pitching

- The added volume from the design ensures a reduced pitch response to waves.

- Consistent speed maintenance

- Vessels experience less speed loss in challenging sea conditions with the X-BOW design.

- Splash-free journeys

- The X-BOW reduces spray, keeping the deck drier and safer.

Developing the maritime experience

The X-BOW (and later, the X-STERN) is one of ULSTEIN's main contributions to maritime history. X-BOW vessels are being built at shipyards on many continents. Currently, more than 100 vessels with this bow concept are being constructed or are sailing around the world.

How does the X-BOW work?

The X-BOW introduces the gentle displacer, a tapered fore ship shape with a different volume distribution and sectional angles, resulting in a wave-piercing effect at small wave heights and reducing pitching and bow impact loads in bigger seas. The X-BOW has more displacement volume starting from the waterline when comparing fore ship volumes with more conventional, bulbous bow shapes.

The experience is quite amazing. I cannot imagine myself ever travelling with a conventional bow vessel again in winter time.

Instead of just rising on the waves and dropping with colossal force, the X-BOW® can distribute the force more evenly across its surface – enabling the ship to remain more stable during poor weather conditions, increasing comfort for passengers and crew alike. And because it uses less fuel to get through the waves, it also helps to save energy.

It’s a totally different experience! You don’t feel the sea. In big seas, I kept waiting for the slamming, but it never came. Other ships can only keep half the speed.

Comfort and safety

From a Health, Safety & Environment (HSE) point of view, reduced accelerations and slamming forces mean less wear and tear on people and equipment. The X-BOW has very little spray, so the deck will more easily remain dry behind. It takes very little water on deck to start being a hazard, or simply a nuisance.

In her right element when head seas get rough

The X-BOW vessel is in her right element when in the more harsh environments. In rough head seas, the slamming will be reduced, resulting in reduced vibrations. This is not only a question of comfort, but also the security for those travelling on the vessel. This is where the X-BOW design excels. And this becomes stories remembered and told by the crew and passengers on these vessels.

Proven design - see our references

Statements from X-BOW users

With feedback like ‘amazing experience’ and’ 'I’ll never again work on any other type of vessel in winter’ being stated by crews on X-BOW® vessels, it is hard to ignore the impact this hull innovation has had since it first appeared in 2005.

More insights

The ULSTEIN X-BOW® – Beautifully bold. Brilliantly efficient

Some say it’s cool. Others call it ugly. We say it’s unapologetically different — and that’s precisely the point.

The ULSTEIN X-BOW® turns traditional ship design on its head. Literally. By flipping the conventional bow shape, we've created a safer, sleeker, and stronger way to sail. This isn't only about looks. It's about leading the future of maritime design.

And guess what? It works.

The X-BOW® experience

- The X-BOW® makes a huge difference in sea behaviour. It splits the wave energy and reduces the slamming impact. Successfully proven in more than 100 ships, the hull shape has recently become a game changer for expedition cruising. Yachts will be next.

ULSTEIN X-BOW® - how it started

- When times are tough, it is still possible to nurture and grow good ideas. That’s the story behind the ULSTEIN X-BOW® hull line design, which upon its introduction in 2005 literally turned the image of the ship’s bow upside down.

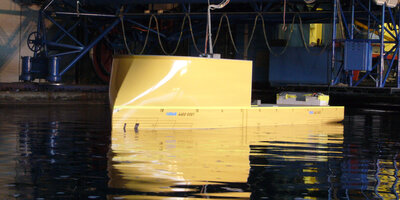

X-BOW® tank test and real-life comparison

When new hull designs are undergoing tank tests, a scale model must endure various waves and wave length conditions. We have performed model tests and comparative model tests for X-BOW hulls and bulbous bows in areas such as supply, seismic, offshore construction, drill, short-sea and anchor handling tug supply.

X-BOW® and X-STERN e-book

Learn more about the key benefits of the X-BOW and X-STERN hull lines.

Registration is required to access the e-book.

Redefining maritime efficiency

Experience transformative maritime efficiency with Ulstein's designs. We're setting new benchmarks in sustainable seafaring excellence by bridging fuel optimisation with heightened comfort and safety.

X-BOW®

The ULSTEIN X-BOW®, the inverted bow concept, redefined marine engineering. The bow concept was launched in 2005, together with the first shipbuilding contract, and gained immediate interest from shipowners. The X-BOW hull line design has been tried in most weather conditions.

X-STERN®

The X-STERN introduces the documented X-BOW® effect to the aft ship, harnessing the benefits of improved safety for crew and equipment, increased flexibility in operations and reduced fuel consumption.

TWIN X-STERN®

Imagine a vessel with the agility of a 4-wheel-drive but on the open seas. That’s the ULSTEIN TWIN X-STERN®, renowned for its unparalleled manoeuvrability. Its unique features distinguish it from others, and its exceptional quality lies beneath the waterline.

U-STERN®

Innovative monopile installation with ULSTEIN U-STERN

The offshore wind industry faces challenges with larger monopile foundations.

Our patent-pending ULSTEIN U-STERN offers a safer, smarter, and more competitive solution for transporting, upending,

and installing large monopiles on DP.