For the first time the fabricated blocks have come together for assembly in the dry dock and the vessel will start to take shape, weeks ahead of schedule. This is the next significant step in bringing Alfa Lift to the market, following the steel cutting ceremony that took place on 1 March this year.

This milestone was marked with a keel laying ceremony on 25 September. OHT's CEO Torgeir Ramstad commended the hardworking people at CMHI and key suppliers, having made great progress since the first milestone in March.

'We have worked together with the shipyard in an open and cooperative way to ensure the utmost quality of construction. Because OHT places a high degree of importance on quality' said Mr. Ramstad.

'According to our customers our vessel will be ground-breaking and will serve the growing offshore wind market for decades to come. The word "growing" is perhaps not precise enough to describe what is happening in the offshore wind market'.

Blog article: 5 stages in the lifecycle of an offshore wind farm

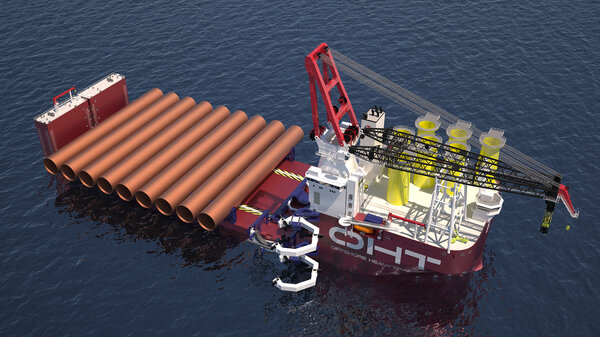

The Subway Alfa Lift vessel of Ulstein design will be the largest and most innovative, custom-built offshore wind foundation installation vessel in the world. The next major milestone will be the launching ceremony in 2020. The vessel is due to be delivered 2022.

Blog article: Dedication to offshore wind

OHT (Offshore Heavy Transport) is a heavy transport and installation contractor and experienced vessel owner/operator with integrated in-house operations, engineering, technical and commercial management.

OHT specializes in transporting oversized heavy cargoes for various markets including Oil & Gas, Offshore Wind and large infrastructure projects. Their new build vessel of the Alfa Lift design will be their first vessel built specifically for the offshore wind market.