Many ship owners and ship yards, having been well established within offshore oil and gas, are now looking to other market segments, such as the offshore renewables industry. Ulstein is one of the companies who has been through this business transformation. The past few years we have entered into contracts ranging from planning and advisory, through to concept, basic and detail designs to ship construction, pre-commissioning, commissioning, testing and delivery of final offshore wind vessels.

We can assist in your business transformation too.

Since the early 1970s, we have built and designed vessels for the offshore oil and gas industry, many of them have operated successfully for many years in some of the world's roughest offshore areas. Offshore wind is a new branch within offshore, and our know-how of robust vessel design ensures thoughtfully planned solutions to give he best financial result for the ship owner.

This is how we can support:

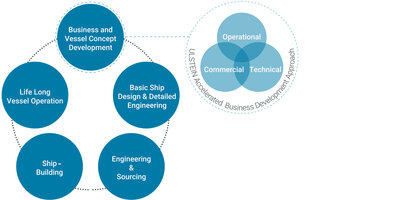

Step 1 - Accelerated business development approach

? when initialising a project to present to stakeholders

Some projects originate from novel ideas, or when an initiating partner sees an opportunity, but needs financial support.

This calls for the development of a structured business plan and concept solution to present to stakeholders, which will reduce time from business idea generation to commercial realisation. This strategic plan will assess the best possible match in operational, commercial and technical aspects of the vessel.

Strategic plan package

The package includes presentation material with conceptual design illustrations of the vessel from various angles, suggested performance and capacity specifications. Performance and capacity choices are taken based on the factual operational needs.

There is much money, and emissions, saved in reducing max performance from 14 knots to 12 knots, unless 14 knots speed is necessary to fulfil operational demands, to name one example.

With our background in ship design, shipbuilding and electrical & control systems, Ulstein is uniquely positioned to guide customers through the fleet renewal and vessel investment decision-making process. We call this an accelerated business development process.

Step 2 - Basic design package

? the choice is made, let's go for it!

You've made the decision - you need a vessel to perform a specific type of operation, and the basic design now needs to be established.

The best results evolve if the ship owner and the ship designers work closely together, involving all design disciplines; naval architecture, hydrodynamics, structure, stability, weight, machinery and electrical. Services include motion studies, feasibility studies, calculations and testing. The result will be an optimised, purpose-designed ship, dedicated for its planned operations.

In the process of developing the basic design, choices can also be made on project management, construction yard and yard supervision and follow-up, as well as main equipment and solutions which can enhance performance.

Step 3 - Detail design comprehensive package

- The vessel's process of becoming realised

In the detail design phase, the engineering disciplines are getting involved, including HVAC, electrical, hull, outfitting and accommodation. There is flexibility to adjust the basic designs to meet needs and standards.

A comprehensive engineering package and a 3D model of the complete vessel are developed, together with a general arrangement (GA) plan of the vessel. The extensive package includes the owner's request for site supervision and site support, construction and installation, testing and documentation, until delivery.

Step 4 - Vessels at work

Before leaving the yard, the vessel is equipped with solid documentation from the ship yard and the ship design company. After-delivery support can include redesign, conversions, retrofits and modifications, system and product upgrades and updates, and new calculations.

We offer digital services, ranging from integration of infrastructure on the vessels (ULSTEIN BLUE BOX?), which enables automated access to selected data sets to advanced operability analysis with extended instrumentation. The digital services are also available for newbuilds and vessels of external designs.

Ulstein also carries out field trips on vessels of Ulstein design, which help us stay updated on issues and solutions needed to be further developed and improved.