At the heart of this transformation are subsea cable networks, largely unseen yet carrying most of the world’s data traffic. They are essential not only for everyday connectivity but also for defence, finance, and emergency services. A single disruption can ripple across economies and compromise security.

Why does this matter

Every new cable project represents an investment in stability and progress. From enabling cloud services and financial transactions to supporting defence communications, subsea cables are fundamental to both civilian and strategic operations. Their installation and maintenance require vessels designed for precision, reliability, and resilience in challenging offshore environments.

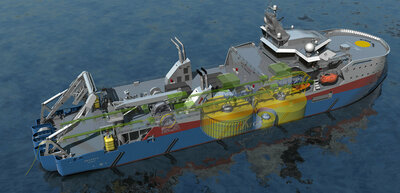

The ULSTEIN SX209 fibre maintenance CLV:

Ship design, shipbuilding, and power & control services

As this sector evolves, maritime expertise plays a crucial role in making these projects possible. Ulstein has long worked at the intersection of design, construction, and integrated systems, developing solutions that help vessels operate safely and efficiently under demanding conditions. By contributing knowledge and technology across the value chain, we support the infrastructure that keeps the world connected.

The ULSTEIN SX228 Fibre-optic CLV:

From the current workforce to the new generation

Ulstein Verft has newbuilding and aftermarket capacities, including a covered dock, several quays and numerous cranes with maximum single lifts up to 600 tonnes. We have in-house design and engineering teams that take on advanced projects. Based on our long offshore experiences, our latest ship design concepts include several fibre-optic CLV vessels.

The focus of the new generation of vessels is not only to do the job efficiently, but to do so with the lowest environmental footprint.

We implement our X-BOW solution on most of the vessels designed to operate in tough conditions. The X-BOW legacy includes more than 100 vessels, most of which are offshore vessels, and have excellent seakeeping capabilities, reduced motions, increased operability and high comfort. The hull shape alone reduces fuel consumption by more than 5 per cent.

Ulstein’s expertise in the fibre-optic vessel market

The installation of fibre-optic cables requires precision and advanced capabilities. Over the past two years, Ulstein has developed a series of concepts for the next generation of fibre-optic cable-laying and repair vessels. The concept design for Megamas Resources is one example.

Ulstein has also proven experience in complex vessel fibre-optic conversions, including the successful transformation of Normand Cutter and Clipper. Projects such as these demonstrate our ability to adapt advanced offshore vessels for new markets, integrating specialised systems and ensuring operational reliability.

This combination of technical expertise and project execution makes Ulstein a trusted partner for fibre-optic vessel design, newbuilding, conversions and other demanding projects.