Key findings:

- Operational data insight:

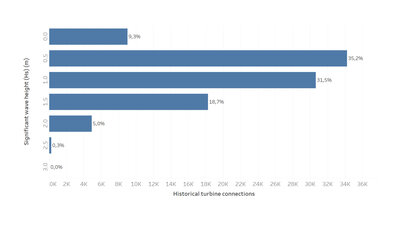

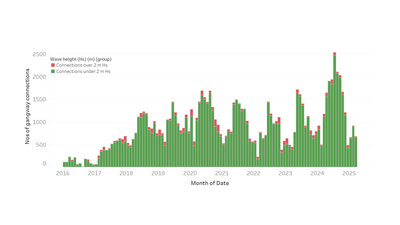

- Analysis of open data from 20 different walk-to-work vessels' GPS positions and 100,000 W2W gangway connections from 2016 to 2025 indicates that the vast majority of W2W operations are conducted at wave heights below 2 metres Hs.

- Design efficiency:

- Unlike most W2W vessels designed for higher sea state conditions, the SX250 is optimised for conditions up to 2 metres Hs, making it a cost-efficient solution.

- Fleet optimisation:

- The SX250 can effectively handle the bulk of W2W operations, allowing shipowners to deploy only one larger W2W vessel for more demanding conditions, thereby optimising fleet utilisation and operational costs.

Flexible topside solutions

The vessel can be customised with different arrangements and topside equipment, allowing it to adapt to various operational needs and making it easy to repurpose for new tasks. The vessel concept design relies on existing off-the-shelf hardware and technologies to ensure effective W2W operations while reducing CAPEX and OPEX.

Depending on operational needs, various setups can include a gangway system for personnel/goods, a daughter craft, a deck storage container, a work or observation ROV, or a fast rescue craft/workboat.

Implications for the industry

The SX250's design fulfils the operational needs of the majority of W2W tasks, proving to be a versatile and cost-effective solution. This vessel can significantly enhance operational efficiency and safety, providing a reliable option for shipowners looking to streamline their fleets.

Ulstein's SX250 is poised to become a cornerstone in the w2w vessel market, demonstrating that targeted design based on real-world data can lead to superior performance and operational success.

Many wind farm operators perform their large maintenance campaigns during the summer season. As reflected in the figure below, the number of connections doubles with respect to the winter season. In such summer campaigns, the resulting operability of SX250 is even higher, as historical activity shows that less than 3% of all the gangway connections performed between May and August were performed above 2 m Hs.

Cutting costs in W2W operations: A new approach to vessel design

Offshore wind farms are currently serviced using Crew Transfer Vessels (CTVs) or helicopters for day operations, and Service Operation Vessels (SOVs) for extended periods. What if there were a CAPEX-smart design that reduces building costs by over 50% compared to an SOV and supplement the SOVs on most tasks?