Reliable, high-quality solutions

We deliver advanced newbuild vessels, as well as conversions, upgrades, surveys, and repair projects. Newbuilds are based on both in-house and external designs developed in close cooperation with owners. Each assignment is approached with the same ambition: to deliver reliable, high-quality solutions that perform as intended throughout their operational lifetime.

A partner for demanding shipbuilding projects

Selecting a shipyard is a strategic decision, whether for a newbuild or an extensive modification of an existing vessel. Quality, expertise and delivery precision are essential factors when handling technically complex projects with high operational and regulatory demands.

Ulstein Verft understands the importance of predictability. Delivery schedules, docking slots and operational availability are critical to shipowners, and our project execution is therefore based on realistic planning, transparent processes and close collaboration throughout the project lifecycle.

With extensive experience in newbuilds, conversions, and service projects, Ulstein Verft has demonstrated the ability to manage complexity, coordinate multiple stakeholders, and accommodate changes while maintaining control of quality, cost, and progress.

Quality as a foundation for long-term value

For complex vessels, quality is defined both by onboard experience and by technical robustness, safety and reliability. Efficient logistics, well-functioning systems, safe operations and a high standard of finish are essential – whether the project involves new construction or upgrading an existing vessel.

At Ulstein Verft, quality is built into every phase of the process – from engineering and production planning to construction, outfitting, testing, surveys and final delivery. A thorough and systematic approach reduces risk, limits downtime and contributes to lower lifecycle costs and higher vessel availability.

Engineering strength and design flexibility

Ulstein Verft builds on extensive engineering competence developed through decades of working with advanced vessels. Key strengths include hull optimisation for year-round operations, propulsion solutions with built-in redundancy, bridge and control room integration, and safe, comfortable accommodation solutions.

Our engineering capacity provides flexibility across project types. We are experienced in handling design maturity variations, retrofit integration and change requests – whether driven by regulatory updates, operational needs or owner preferences. Close collaboration with shipowners, external designers, class societies and interior architects ensures that design intent and technical requirements are fully realised.

A compact and efficient yard

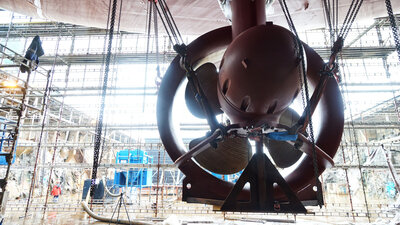

The dock hall is the centre of production at Ulstein Verft and enables construction, conversion and repair work in a sheltered, controlled environment. This supports consistent quality, high precision and efficient workflows across both large and small-scale projects.

The compact layout of the yard, with production facilities, warehouses and outfitting workshops located in close proximity, ensures short communication lines and effective coordination. Design, engineering and production teams work closely together, enabling rapid decision-making and practical problem-solving.

Long-term ownership and industrial continuity

Ulstein Verft is part of a family-owned maritime group with more than a century of industrial history. Long-term ownership provides stability, continuity and a strong commitment to sustainable value creation – for customers, employees and partners.

Over time, the yard has delivered a wide range of vessels and maritime projects, including newbuilds, conversions, upgrades, repairs and surveys. This breadth of experience has built a deep understanding of complex shipbuilding and lifecycle support across multiple vessel types and operational profiles.

Predictable cost and delivery

In complex maritime projects, predictability is often more valuable than the lowest initial price. Delivery on time, at the agreed quality and within the agreed commercial framework, is essential for the shipowner’s overall success.

Ulstein Verft’s cost estimates are based on experience and realistic assumptions. Changes during the project are handled through structured processes and agreed change orders, ensuring transparency and trust between yard and shipowner.

Our objective is clear: to deliver complex maritime projects at the agreed quality, at the agreed price, and at the agreed time.