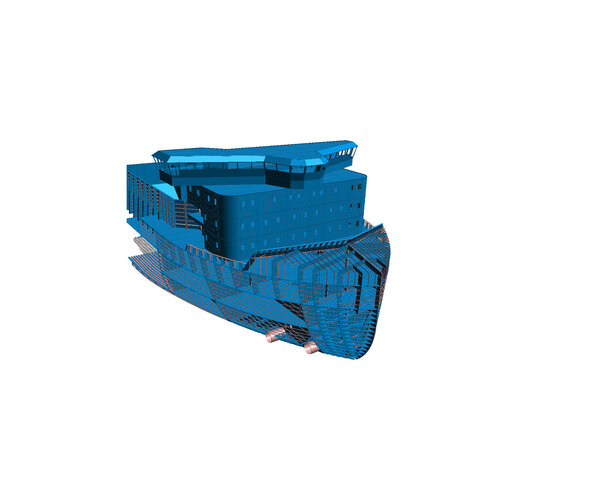

The scope of work includes the selection of vessel main equipment with integration engineering plus the start of detail design. Awarding this contract is intended to advance the engineering work, ensuring the vessel is on schedule to meet its operational target of Q2 2024.

"It is a privilege to work with Ulstein on this landmark project as they continue to bring global best practices, expertise and creativity to the design of this first-of-its-kind U.S. vessel", says Mike Greenwood, sr. project sponsor at GLDD. "Given the priority the White House has placed on the offshore wind market, special-built vessels such as this will serve as the critical foundation for the advancement of this key industry."

According to a World Energy Report analysis, more than 30 major U.S. offshore wind projects are forecast to be developed over the next 10 years, injecting nearly $88bn of CAPEX and a $2.8bn annual OPEX opportunity across marine-related support industries.

"Despite the Covid-19 pandemic, the design process and cooperation with GLDD has been highly productive and efficient", adds Edwin van Leeuwen, managing director at Ulstein Design & Solutions B.V. "All credits to both GLDD and Ulstein project teams that have been working on this project since June 2020 from their home offices. Ulstein's strength and added value to customers are reflected in this engineering contract. This is the result of the close cooperation between our design and engineering teams in the Netherlands, Norway and Poland as well as using Ulstein's long shipbuilding competence.

The vessel will be built at a yet-to-be-selected US shipyard. To meet general US working practices, Ulstein therefore developed the design completely in the imperial system, rather than converting metric dimensions at a later stage.