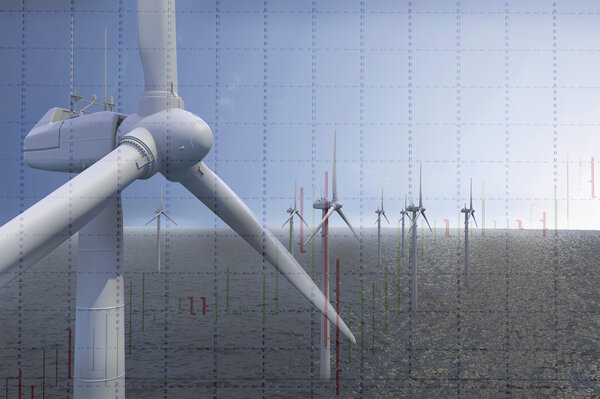

Offshore wind is one of the renewable markets expected to increase significantly in the years to come. The global offshore wind market is estimated to grow by 16% through 2020.

Offshore wind farms experience steadier and stronger winds and can, therefore, produce more energy. The new establishments are further from shore and in deeper waters.

The SOV has been taken in use for longer distances

At some point, overnight stays for the service technicians become necessary, and other transport tools must replace the transport normally done by Crew Transfer Vessels.

A CTV vessel typically transports service technicians and spares from the onshore base to and from the offshore wind farms daily. This means that the distance from shore cannot be too far, with a maximum transfer time of 90 minutes. If the sea conditions are too harsh, the transfer can be carried out by helicopter. The required tasks cannot include heavy spares or tools in these cases.

An SOV vessel (Service Operation Vessel) is a dedicated vessel that carries service technicians, equipment, spares and tools to and from offshore wind farms. The vessels function as floating hotels, workshops and warehouses. They are larger than CTVs, and can typically carry 60-90 people. The vessels transit to the wind farms and stay positioned there for a longer period on time. They must have very good seakeeping standards, both in transit and when positioned, for the wellbeing and safety of the on-board personnel.

The SOV vessels are equipped with a motion-compensated walk-to-work gangway for the safe transfer of technicians from the SOV vessel to the wind turbines. The technicians can also be transferred from the SOV vessel to the turbines via the smaller CTVs stored on board. Additionally, the crane on the SOV can hoist equipment and spare parts from the vessel onto the wind turbine tp (transition piece) platform.

Getting the best from Oil & Gas in Offshore Renewables

Offshore wind is a new segment in the offshore family, and knowing how the weather can impact the vessel is of great value when developing designs and solutions for offshore renewables.

The Norwegian maritime cluster has already gained much knowledge and references related to the installation, operation, and maintenance of various offshore wind farms. This includes equipment and solutions, ship designs, and shipbuilding. Innovative, award-winning solutions have evolved, which can help reduce the levelized cost of energy (LCOE).

SOV vessels come at a high investment cost. However, as the prognoses for future growth in far-from-shore wind farms are this potent, the timing is now.