Most new jack-up designs are featuring a battery hybrid system in addition to diesel gen sets, with a future option for hydrogen powered fuel cell system. The downside however of a high-power battery energy storage system (BESS) is its heavy weight and cost. That is not beneficial for a WTIV design, where weight savings are essential for minimizing Elevated Weight and optimising the Variable Deck Load.

Taking the industry from hydrogen prepared to hydrogen powered

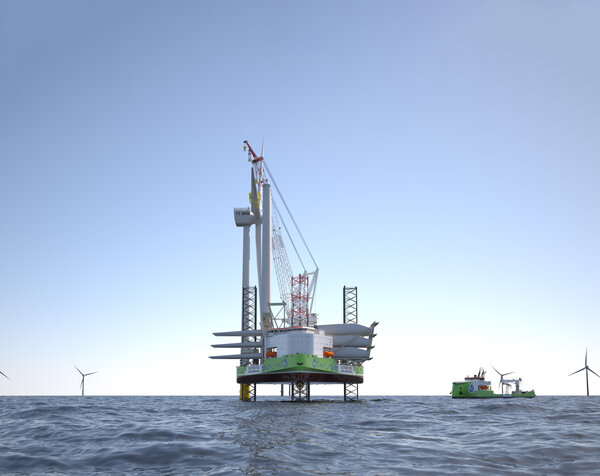

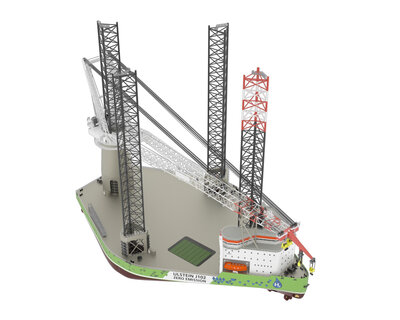

Rather than to opt for technology to be matured to perfection and make a design that is prepared for future hydrogen powered fuel cells, Ulstein has taken the pragmatical, yet realistic approach. 'We have carefully analysed the operational cycle of WTIVs and looked at the power demand in the various modes of operations', says Ko Stroo, Product Manager at Ulstein. 'This analysis showed that ca. 75% of its time, a WTIV is in jacked-up position performing crane operations. Using a combination of a hydrogen fuel cell system and a relatively small battery energy storage system (BESS) is then sufficient to meet the overall power demand on board and crane peak loads.'

Attractive business case for turbine installation vessels

'The same design philosophy as on our first hydrogen powered SX190 design, resulted in a much more attractive business case when applied to a turbine installation vessel', states Edwin van Leeuwen, managing director of Ulstein's Rotterdam design office.

The hydrogen hybrid system of the ULSTEIN J102 design has been developed in such a way, that future developments in hydrogen technology can easily be fitted into the vessel without major modifications. 'The limited availability of hydrogen bunker infrastructure in ports is often seen as a major hurdle. With our modular storage lay-out, we want to break the chicken and egg dilemma', continues Stroo. 'It creates flexibility to operate the vessel worldwide, even when bunker infrastructure is not yet present.'

'The strong focus on renewable energy and emission reduction to meet worldwide climate goals should also be reflected by investments in cleaner operations when installing offshore wind turbines', says Edwin van Leeuwen. 'Hydrogen is one of the most promising zero-emission fuels for offshore vessels and we want to be leading in developing sustainable ships.'

Main features of ULSTEIN's J102 hydrogen-hybrid zero-emission design are:

- CO2 reduction per year: 4,000 mt

- Emission reduction per installation cycle: 25 %

- H2 fuel cell system: PEM fuel cell

- H2 storage system: 7 x 40ft containers compressed H2

- Battery energy storage

Ulstein participates in the UN Global Compact program supporting the UN Sustainability Development Goals.

More on how we want to build a a sustainable maritime legacy here.