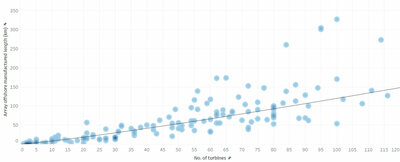

The expansion of the offshore wind market has brought about significant changes in the cable-laying industry. More turbines mean more cables to install, which means a greater need for carousel capacity on the cable-laying vessel.

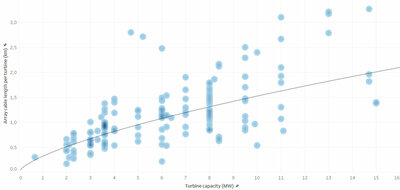

However, the length of the installed cable is dependent not only on the number of turbines but also on their size. The average cable length per wind farm has grown from 30 km in the 2000s to 80 km in the late 2010s and is projected to surpass 100 km by the end of this decade. The longer the required cable, the greater the carousel and vessel capacity needed.

Moreover, as turbines get bigger, the cable’s diameter and weight also increase, tripling the impact.

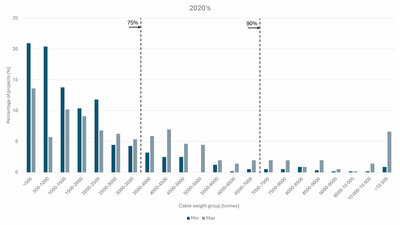

How cable weight has increased in the offshore wind industry

A review of cable length and weight across wind farms reveals that in the 2010s, 75 % of installations used inter-array cables that weighed less than 2,500 tonnes. However, to match this percentage for wind farm projects in the 2020s and 2030s, the cable weight increases to 3,500 and 4,500 tonnes, respectively.

Furthermore, the cable weight has risen from 4,000 tonnes in the previous decade to 6,000 tonnes in the current period for 90 % of installations.

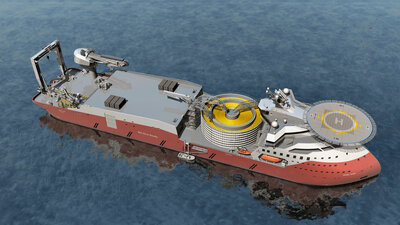

The ULSTEIN SX238: A future-ready solution for inter-array operations

The ULSTEIN SX238 boasts a 6,000-tonne cable capacity and offers an optimal mix of capacity, cost, and efficiency for inter-array cable laying operations.

ULSTEIN X-BOW feature

The vessel features the innovative ULSTEIN X-BOW design, which excels in harsh conditions. In rough head seas, the X-BOW design minimises slamming and reduces vibrations for a more comfortable and safer journey for those on board.

Net Zero Ready - pioneering sustainability

The ULSTEIN SX238 is not just about functionality. It is also about sustainability. The vessel is Net Zero Ready, equipped for dual fuel operation with methanol and comes with a battery capacity of 1,130 kWh for spinning reserves and peak shaving.

Under-deck carousel setup

The ULSTEIN SX238’s cable storage system is split into two carousels, both located under the deck for protection against the elements. Each carousel has a diameter of 20.5 m and a cable capacity of 3,000 tonnes. The dual-carousel setup ensures seamless cable handling during installations.

Efficient CPS handling

The vessel can store up to 500 tonnes of cable protection systems (CPS) on deck. The CPS can be stored in containers, handled, and assembled on top of the hangar. Then, it is transferred to the cable deck via chutes and hatches, leading directly to the firing line.