Understanding the value of data

Keywords: digitalisation, shipping, BlueBox, value, performance

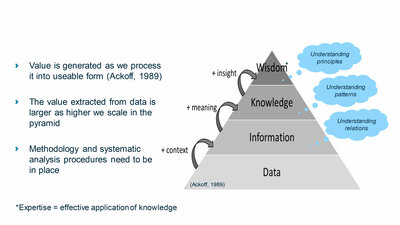

One of the most common mistakes in implementing digitalisation is believing that data will solve all the problems. Data alone has no value. The true value of data is extracted when it is analysed and interpreted and corrective actions are implemented. Field expertise is essential to interpreting results and suggesting actions for improvement. Ulstein, as a builder and designer, has the expertise to support you on your digital journey.

What is the value of data? Ackoff (1989) suggests that "data, like metallic ores, are of no value until they are processed into a useable (i.e. relevant) form". As Ackoff points out, the millions of data records generated onboard vessels are useless if they are not explicitly used. Of course, many of them already have a purpose onboard the vessel. E.g. measure the oil temperature of an engine and trigger an alarm if the value exceeds a threshold. However, the value of those data signals can be further enhanced or augmented by exploring other complementary interpretations and uses. Why should oil temperature not be used to predict malfunctions in the engine or planned maintenance activities?

The more we process data (not data manipulation), the higher its value. Information typically reflects the contextualization of data. Data monitoring and reporting are sources of information. They support decision-makers to answer questions such as where a vessel is operating. How much fuel has been used? What kind of cargo is it carrying?

Understanding how to increase the effectiveness of vessel operations requires knowledge. Knowledge results from extracting meaning from information, which requires complementary field expertise. Expertise in vessel design and operations is essential to interpret data and information from vessel operations and identify and propose improvement areas.

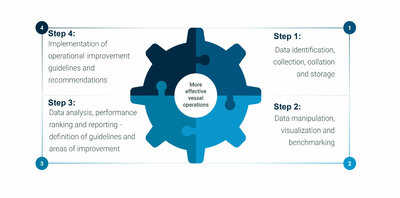

Four digitalisation steps towards value creation

Ulstein has developed a four-step digitalisation approach to gradually extract and interpret value from data. The implementation of the services can be carried out stepwise (start with Step 1 and continue as demand requires).

Step 1: Data identification, collection, collation and storage

Selecting the right data inputs is essential for a successful digital strategy. In a preceding article, we have suggested our four-step approach for selecting and effectively identifying the right data signals.

BlueBox smartly enables data retrieval and storage. Due to its flexible configuration, it enables its integration in "almost" any vessel. It allows data collection from multiple systems onboard according to the needs of the digital strategy.

Step 2: Data treatment, visualization, and benchmarking

Data visualization is the first stage of data analysis, interpretation, and display. Time series-based data visualization can be important for real-time onshore and offshore decision-making and for better understanding and studying past operations to improve for the future. Grafana or X-Connect Studio are good platforms to start monitoring your vessel operations.

Step 3: Data analytics, performance ranking and continual work improvement

Data visualization is not enough to understand the causes, effects, consequences, and implications of individual factors relating to the vessel's performance. To understand the effect of design, operational, and commercial decisions on the overall operating performance of the vessel, we need to rely on fact-based analytics of its operations and the behaviour of the people onboard.

Analyses combine data experts, ship designers, and people with experience operating the vessels. This combination ensures that results are interpreted correctly and contextual factors not registered in the data (operational practices, crew shifts, operational requirements, etc.) are considered.

As of now, Ulstein offers a set of modular analytics services as defined below:

- SM1. System logistics, routing, and operational profile management

- SM2. Speed utilization

- SM3. Seakeeping performance, operability, and sea-sickness profile of the vessel

- SM4. Fuel consumption analyses benchmarking and performance ranking

- SM4.1. Dynamic environmental indexing (EEOI, etc)

- SM5. Energy management (power plant utilization)

- SM6. Trim & propulsion performance analysis

- SM7A. Crew behaviour and operational performance (based on data facilitated and provided by the owner)

- SM7B. Crew behaviour and operational performance (based on data captured from a field study, including stay on board)

Step 4: Implementation of operational improvement guidelines and recommendations

The last stage in the process towards more effective ship operations, but not least important, is the implementation of corrective actions and follow-up. Once performance improvements have been identified and corrective actions proposed, the operators and crew should be prepared to carry them out and live by them accordingly. This can be performed based on training workshops with operators and other relevant personnel or onboard or web-based field studies, including training sessions.

Would you like to know more?

Explore our featured articles below or get in touch.

We are eager to explore how digitalisation possibilities can improve the effectiveness of your vessel operations.