From erosion prevention to pipeline protection

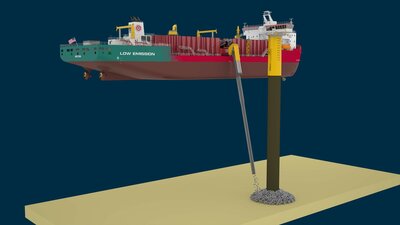

Subsea rock installation may be a niche discipline, but it plays a vital role in many offshore projects. Rocks on the seabed, for example, prevent erosion around offshore foundations. These ‘scour protections’ are essential in ensuring the longevity and integrity of wind turbines, oil platforms and other offshore structures. In addition, subsea rocks also shield underwater pipelines, power cables and communication lines from accidents and external hazards like sabotage.

Accurate subsea rock placement

Ulstein Design & Solutions BV has been at the forefront of designing and engineering vessels purpose-built for this challenging task for over two decades. These subsea rock installation vessels require precise rock placement capabilities, which demand the integration of complex handling equipment. Among Ulstein’s standout designs are Flintstone (DEME Offshore), Bravenes (Van Oord) and Acadia (GLDD), each a tailor-made solution reflecting close collaboration with its owner around its specific handling equipment.

At the heart of these vessels is a fall pipe reaching down to the seabed for placing the rocks accurately. In shallower water, the pipe is typically a rigid structure deployed from the vessel’s side. The US-flagged Acadia employs such a system. Ulstein played a central role in the development of both the rigid fall pipe and the rock transport mechanism, which uses excavators and conveyors to deliver rocks from onboard storage to the seabed.

Distinct designs for seabed rock installation

Despite some visual similarities, Flintstone and Acadia are markedly different. Designed for operations in water depths of up to 2,000 metres, Flintstone features a moonpool through which the fall pipe is launched and recovered. It also incorporates a remotely operated vehicle (ROV) to accurately place the rocks and survey the installed rock bed. Both the fall pipe and the ROV have a handling system integrated into the vessel.

When GLDD approached Ulstein in 2020 to design a 20,000-tonne capacity rock installation vessel, the result was not a replica of previous projects. Ulstein applied its Blended Design approach — an in-depth process evaluating the business case, performance goals, and vessel parameters to arrive at the optimal solution. The outcome was Acadia, a highly efficient vessel with reduced fuel consumption and maximised capacity.

Bravenes, the third vessel in this trio, stands out with Ulstein’s signature X-BOW® to improve seakeeping in the harsh North Sea conditions. Like the other subsea rock installation vessels, she features an advanced Dynamic Positioning (DP) system, but Bravenes has also added the redundancy of DP class 3. Further, she features an innovative handling system housed in the distinctive orange deck structure above its moonpool. This innovative box concept was developed together with Ulstein in parallel with the vessel design and integrates both the fall pipe and ROV systems.

The rock transport system of the Bravenes is a combination of excavators and a self-unloading rock hold. While a self-unloading rock hold is typically covered with hatches, Ulstein pioneered and tested a novel open-top rock hold.

Despite having the smallest rock capacity of the three at 14,000 tonnes, Bravenes is considered the most versatile, able to install rocks near sensitive installations, at various depths, and even in icy conditions. The Flintstone can however reach the deepest water (2000 metres) while the Acadia has the largest rock capacity (20,000 tonnes).

Movie copyrights: Van Oord.

Tailored excellence

Each of these vessels reflects Ulstein’s expertise in integrating cutting-edge naval architecture with complex rock installation equipment systems. Whether it’s Flintstone's deep-sea capabilities, Acadia's large capacity, or the adaptability of Bravenes, they exemplify how thoughtful design can meet specific demands, resulting in subsea rock installation vessels that are sometimes brilliantly simple, sometimes necessary complex.

Proven designs - see our Subsea Rock Installation references

Decades of building state-of-the-art vessels for demanding marine operations have given us a knowledge base and experience guaranteeing the highest standards of quality, execution and delivery.

Shipbuilding worldwide

In addition to Ulstein's yard in Norway, we work with partner yards worldwide. Contact us if you have a specific yard in mind for your next project and would like us to assist.