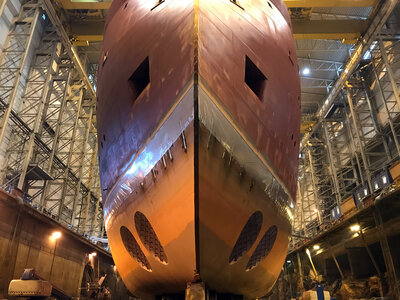

The hull of the vessel arrived Ulstein Verft in September 2019 and in the last few months the work has been focused on accommodation, electrical installations, painting of technical areas and outfitting.

After the hull had been towed into the dock hall, the exterior paint work started, while the interior work continues.

This will be Bernhard Schulte's third vessel which has been designed and constructed by Ulstein. The X-STERN®, which has been developed by Ulstein, is particularly well suited for the offshore wind service industry. With all main equipment and operations in the aft ship, a vessel of this type will naturally operate astern while in-field. The X-STERN design reduces slamming and subsequent vibrations from head seas, and improves rest and onboard comfort.

The first two vessels for Bernhard Schulte are of the SX175 design, while the Yno 315 is based on the larger SX195 design, measuring 93.4 metres in length.

The design has been customised for the tender requirements of the charterer and the ship owner's preferred mission equipment. It has a large, centrally positioned walk-to-work motion compensated gangway & lift tower for personnel and cargo transfers. Furthermore, a 3D compensated crane is available. The optimised on-board logistics includes large storage capacities, of which half is under roof in a controlled environment, and stepless approach to the offshore installations.

In cooperation with the ship owner, Ulstein Design & Solutions has designed a diesel-electric propulsion system assisted by batteries to reduce operating hours on the main engines, save fuel and reduce environmental footprint.